The State Key Scientific Facility (3MW sCO2 system)

The legal entity of the high-efficiency and

low-carbon gas turbine test device project is the Institute of Engineering

Thermophysics of the Chinese Academy of Sciences, and the participating units

are the Energy Power Research Center of the Chinese Academy of Sciences in

Jiangsu Province and the Advanced Energy Power Research Center in Pudong,

Shanghai. The Chinese Academy of Sciences supports the construction of this

facility by relying on relevant scientific and technological advantages as well

as the early research and construction and operation management experience of

several large scientific devices.

Through the construction of this testing

facility, the Institute of Engineering Thermophysics of the Chinese Academy of

Sciences will establish a complete research platform for turbomachinery

aerodynamics, cooling, stability, and multi fuel combustion chamber testing. It

will have the ability to systematically research various components of gas

turbine compressors, combustion chambers, turbines, and new cycles, and master

the core technology of gas turbine testing equipment. At present, the research

institute has established a high-level research team with excellent quality,

reasonable age structure, complete professional types, courage to innovate, and

unity and cooperation. It has the ability to undertake the construction of

efficient and low-carbon gas turbine test equipment.

Scientific background

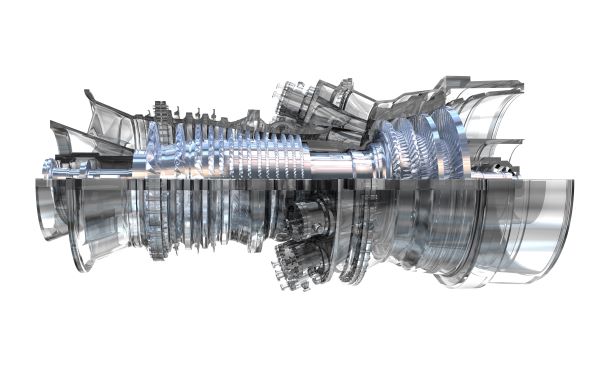

1. What is the high-efficiency and

low-carbon gas turbine testing device?

Efficient and low-carbon gas turbines are

high-temperature, high-pressure, and high-speed rotating thermal

turbomachinery. Their internal aerodynamic, thermodynamic, fluid thermal,

chemical, and solid coupling are complex, and rely heavily on long-term experiments

and data accumulation. A gas turbine is composed of components such as a

compressor, combustion chamber, and turbine, and is the most efficient

(combined cycle efficiency has reached 64.0%) and cleanest (nitrogen oxide

emissions below 25ppm) high-power thermal power conversion device. The gas

turbine testing device is a fusion project of multiple sciences, technologies,

and engineering. This device can provide a practical and realistic experimental

research environment, and is a technological infrastructure for conducting

scientific and technological problems, applications, and development research

on gas turbines, as well as innovative activities.

Figure

1: Experimental setup diagram of high-efficiency and low-carbon gas turbine

2. What is the significant significance of

building an efficient and low-carbon gas turbine test facility?

For a long time, China has been deeply

constrained by the bottleneck of the blank space of high-power gas turbine

testing equipment. There is no fundamental condition for carrying out major

scientific and technological problems in gas turbines, and key scientific data

and basis cannot be obtained. There is no effective accumulation of technology

and talent, and there is a gap of at least 30 years compared to foreign

countries. No product has completed the complete process from basic research to

use and development, and there is a lack of independent technology, products,

and industries. Up to now, China has been stuck in the assembly business

obtained through "market technology exchange", without mastering the

design technology of gas turbines and the manufacturing and maintenance

technology of hot end components. Almost all of the debugging, maintenance, and

repair work of domestic gas turbines are completed by foreign gas turbine

production and sales enterprises. It is an urgent need for the scientific, technological,

and industrial development of gas turbines in China to quickly build efficient

and low-carbon gas turbine testing facilities.

Through the construction and operation of

this facility, we aim to provide a world-class experimental platform for the

efficient utilization of natural gas, clean and low-carbon utilization of coal

energy, as well as cogeneration, renewable energy utilization, fourth

generation nuclear energy, energy storage, process application, and industrial

energy-saving research and development of gas turbine technology. This will

enhance the autonomy of related industries and promote the development of

emerging high-tech industries.

3. What is the main content of building an

efficient and low-carbon gas turbine testing device?

The main construction content of this

project's facilities consists of three matching components: gas turbine

compressor, combustion chamber, and turbine, as well as a cycle test research

system, to support gas turbine components and cycle test research. Including:

compressor test platform, combustion chamber test platform, turbine test

platform, cycle test platform, public system and public engineering.

(1) The compressor testing platform

includes single/multi-stage compressor testing platforms;

(2) The combustion chamber test platform

includes three test benches: high-temperature and high-pressure optical

transparent combustion, full temperature and pressure single cylinder full-size

combustion chamber, and full temperature and pressure single cylinder full-size

combustion chamber;

(3) The turbine test platform includes

three test benches: cooling/sealing test bench, high-temperature nozzle cascade

test bench, and multi-stage rotating turbine flow/cooling comprehensive test

bench;

(4) The cycle test platform includes an

efficient new cycle test bench and a low-carbon supercritical carbon dioxide

cycle test bench;

Figure 2.Shanghai Park Planning

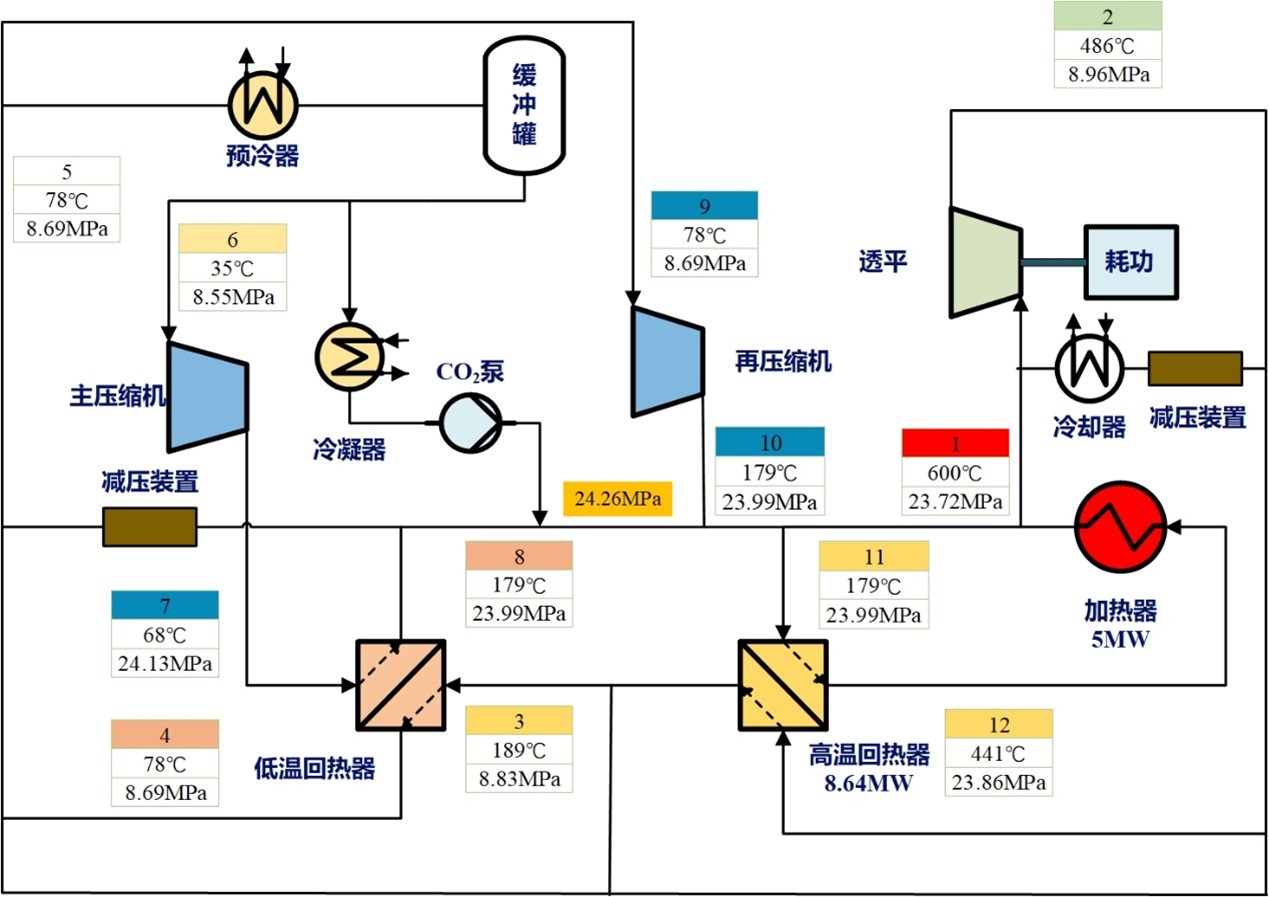

1、 Low carbon supercritical carbon dioxide cycle test bench

1. Platform/System Composition Diagram

2. Scientific objectives

Research the energy conversion laws of

advanced and new power cycles, open up new paths for the development of gas

turbines, and master the technology of efficient and low-carbon power cycle

systems.

3. Main parameters of the test bench

|

|

Unit |

Value |

|

Circulating

flow rate |

kg/s |

≥25 |

|

Preheating

temperature |

℃ |

600℃ |

|

Maximum

pressure |

MPa |

≥24 |

|

Cycle

power |

MWth |

≥5 |

4. Test bench functions

The supercritical carbon dioxide cycle test

bench will provide experimental conditions for conducting supercritical carbon

dioxide cycle and key unit characteristic tests. The test bench can conduct

both supercritical carbon dioxide cycle characteristic tests and key unit tests

such as compressors, turbines, and reheaters that make up the cycle. In terms

of loop characteristics, it specifically includes:

Experimental study on the characteristics

of supercritical carbon dioxide regenerative cycle

Experimental Study on the Start Stop

Characteristics of Cycles

Experimental Study on Partial Load

Characteristics of Cycles

Experimental Study on the Dynamic

Characteristics of Cycles

Experimental research on control strategies

for loops

Experimental Study on Process Optimization

of Circulation

In terms of research on key components of

the cycle, specifically including:

Experimental Study on Characteristics of

Supercritical Carbon Dioxide Compressor

Experimental Study on Characteristics of

Supercritical Carbon Dioxide Regenerators and Precoolers

Experimental Study on Heat Transfer

Characteristics of Supercritical Carbon Dioxide

Experimental study on the characteristics of supercritical carbon dioxide turbines

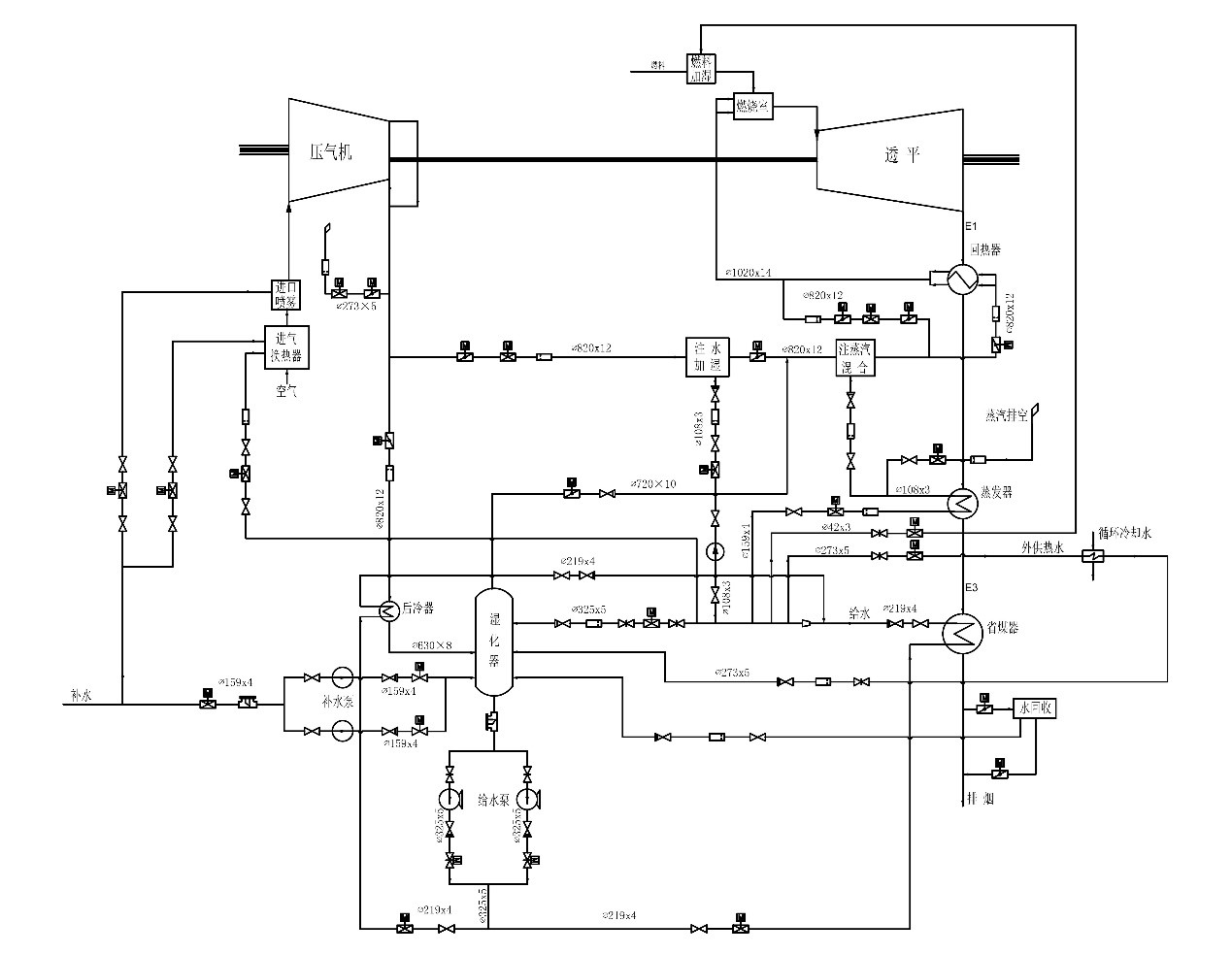

2、

Efficient new cycle test bench

1. Platform/System Composition Diagram

2. Scientific objectives

Research the energy conversion laws of

advanced and new power cycles, open up new paths for the development of gas

turbines, and master the technology of efficient and low-carbon power cycle

systems

3. Main parameters of the test bench

|

Unit |

Value |

|

|

Thermal

power |

MWth |

≥25 |

|

Flow |

kg/s |

≥40 |

|

Pressure |

MPa |

≥0.7 |

|

Load

power |

MW |

≥10 |

|

Loop type |

|

Numerical

heat cycle & Wet air

turbine cycle |

4. Test bench functions

The high-efficiency new cycle test bench is

used to conduct new cycle tests of gas turbines using air as the working fluid,

supporting research on pure power generation and cogeneration of cycles. It can

provide experimental conditions for users to conduct research on the

characteristics of efficient new cycle systems, as well as for users to study

the performance of key units and their impact on cycle characteristics.

The thermal cycles that can be studied

based on this cycle test bench include: gas turbine reheat cycle, water

injection/steam reheat cycle, wet air turbine cycle, etc. For the above cycle,

this test bench is capable of conducting experimental research, including:

Experimental Study on the Start Stop

Characteristics of Gas Turbine Cycles

Experimental Study on Dynamic

Characteristics of Gas Turbine Cycles

Experimental Study on the Characteristics

of Gas Turbine Cycle Affected by Environmental Temperature

Experimental Study on Partial Load

Characteristics of Gas Turbine Cycle

Experimental Study on Control Strategy of

Gas Turbine Cycle

Experimental Study on the Thermoelectric

Ratio Adjustment Characteristics of Gas Turbine Cycles

Based on this cycle test bench, the

characteristics of key unit technologies and their impact on cycle performance

can be studied:

Experimental research on a new type of

intake cooling technology for compressors

Wet compression test research

Experimental Study on Wet Air Combustion

Experimental Study on the New Heating and

Humidification Process of Compressed Air

Experimental research on a new type of

reheater

Experimental Study on New Type of Exhaust

Water Recycling and Utilization

Related links

http://www.iet.cas.cn/gxdtrqljsyzz/yjxt/xhsypt/

User login

Important Dates:

Abstract Submission

Extended Abstract Submission

Notification of Abstract Acceptance

July 15, 2024

Submission of Full-length Paper

(still open for New submission of abstract)

July 30, 2024

Paper Acceptance Notification

Aug 15, 2024

Early Bird Registration

Sep 20-24, 2024

Formal Conference

Organized by:

Co-organized by:

Under the auspices of:

Sponsors: